The Bambu Lab X1-Carbon is Bambu Lab’s flagship machine, and has caused quite a stir throughout the 3D printing industry. What Bambu has managed to do in a short amount of time is demonstrate rapid innovation in many technologies that had been taken for granted within the industry. They’re the company that essentially brought high-speed machines to the masses, and with the X1-Carbon, they have produced a machine capable of extremely fast, high-precision printing at a very reasonable price.

But speed and quality aren’t the only factors that have pushed Bambu Lab’s machines to the forefront of the best 3D printers we’ve tested, especially the X1-Carbon. It is also fully compatible with their proprietary AMS system, making multicolour and multi-material prints easy.

What’s more, advanced calibration is built in as standard and ensures easy setup and reliable prints, so you can essentially take the printer out of the box and be up and running in roughly ten minutes.

Another big feature is the printhead that comes as standard, you can print with advanced materials such as PAHTCF and PLACF, giving enthusiasts and professionals plenty of additional options compared to other printers. The X1-Carbon also hits a pretty decent price point, so while it’s by no means entry level pricing, for the features and quality it will suit keen hobbyists and professionals alike, as it’s ultimately far more affordable than many printers it matches or even surpasses in features.

Bambu Lab has created a complete ecosystem, including advanced slicer software and management that can be used directly with the machine through a wired network connection or through the cloud. However, one reason the system works so well is that it’s completely enclosed with closed-source firmware, which limits customisability for enthusiasts. Nonetheless, this results in a very reliable machine that is both fast and produces superb quality prints in a multitude of material options.

Bambu Lab X1-Carbon: Design

Table of Contents

Removing the X1-Carbon from the box and it instantly reveals an extremely high-quality machine with sleek aesthetics and a relatively compact design that will look perfectly at home in any design studio.

After setting the machine down it takes between 10 to 15 minutes to get everything ready to print. Checking over the X1-Carbon reveals some interesting touches, such as the carbon fiber rails, which ensure the machine’s durability and stability. These are very similar to those featured on the P1P, which we reviewed some time ago. However, with the X1-Carbon the machine is fully enclosed, which means you can print with ABS and other high-temperature materials that fare better in a fully enclosed environment.

Inside the machine are extras such as the 1080p camera for monitoring progress in real time. This camera not only provides a live stream from the machine but also enables the AI error detection. If anything goes wrong or there’s an issue with your print, the AI camera will pick it up.

On the front of the X1-Carbon is the beautifully designed touchscreen, which has an intuitive user interface that’s easy to get to grips with, offering different degrees of interaction depending on your experience. The quality of this interface might not be a headline feature compared with the speed and multi-filament printing, however, it should be noted that it’s one of the best out there, being both easy to use and navigate.

As standard, the machine can be used as a single-filament printer, for which it’s very quick and easy to load the filament and start printing. But where this machine really excels is when you connect the AMS (Automatic Material System), which enables you to print with up to 4 materials by default. Further AMS systems can be attached to increase the number of filaments, allowing for both different colours and materials, vastly expanding the use and functionality of the X1-Carbon.

In terms of physical dimensions, the machine measures 389 x 389 x 457 mm, meaning it can easily sit on a work surface. It weighs 14.13 kg, so while the machine itself isn’t large, it is quite heavy due to the glass used for the enclosure and the high-quality frame, which ensures there is little flexibility in the construction. The enclosure is ideal for printing advanced materials such as ABS, which require a warmer environment.

Inside the build area is 256 x 256 x 256 mm, providing plenty of room. The X1-Carbon can print with a huge range of materials and has a maximum hotend temperature of 300°C and nozzle size of 0.4 mm which is made of hardened steel. When it comes to print speed the machine can reach a maximum speed of 500 mm/s with max acceleration of 20,000 mm/s². However, it’s worth noting that when using the AMS system, a cleaning process occurs, so while the machine is very fast, the cleaning and changing of filaments slow things down slightly.

As for material support, having an enclosure around the machine means you can print with a much wider variety of materials than some open systems. With the X1-Carbon, you can print with PLA, PETG, TPU, ABS, ASA, PVA, PET, PA, PC, carbon fiber, and glass fiber-reinforced polymers, giving you plenty of print options.

Bambu Lab X1-Carbon: Features

Specs

Print Technology: Fused Deposition Modeling (FDM)

Build Area: 256 x 256 x 256 mm

Minimum Layer Resolution: 50 microns

Maximum Layer Resolution: 400 microns

Dimensions: 389 x 389 x 458 mm

Weight: 14 kg

Bed: Heated, multipoint mesh leveling

Print Surface: Magnetic PEIcoated steel sheet

Software: Bambu Studio (SuperSlicerbased)

Materials: PLA, PETG, ABS, TPU, PAHTCF, PLACF

Print Speed: Up to 200 mm/s

Taking a look at the range of features the X1-Carbon offers, and the 500 mm/s CoreXY motion system that’s capable of delivering both those high speeds and precision has to be at the top.

Then there’s the advanced calibration system which you can choose to run at the start of each print, this runs through a series of self-checks, ensuring the first layer and all subsequent layers are printed with absolute precision and helps to prevent any miss prints. And of course there’s that AI camera keeping an eye on things as well.

While the CoreXY motion system is impressive what has really made Bambu’s name in the industry is the AMS (Automatic Material System), which sits on top of the machine and takes less than a minute to install. This system enables you to load up to four filaments at a time, feeding them through as needed and all automatically. While the combo version of the printer, the package that we’ve looked at in this review, comes with an AMS system, it is possible to expand on this. Ultimately you can connect up to four AMS, allowing the printer to handle up to 16 different filaments when daisy-chained together.

The machine and the control of the AMS feed is all set-up and controlled through BambuStudio on your Mac or PC or if you decide to make of a change of filament, then this can be done directly through the machine using touchscreen interface. Additionally there’s also an App that can be downloaded to iOS and Android devices called Bambu Handy, here again you have a range of access features that offer complete control over the machine.

When it comes to the working end of the machine Bambu has selected their own hot end which can reach up to 300°C, enabling you to print engineering-grade materials like PAHTCS as well as more standard materials like PLA and ABS. The proprietary hotend and nozzle does limit you to Bambu hardware, however, this also ensures everything works extremely well with the high precision hardware – it also highlights that this is a machine to be used as is, and not to customise with aftermarket parts.

One feature that will appeal to many users is the built-in 1080p camera. This camera supports real-time monitoring, timelapse creation, and those AI-assisted features such as error detection. Since the machine’s launch, AI error detection has been greatly enhanced with relatively regular firmware updates, that help to boost the functionality. The AI camera does help to cut down on print errors and reducing waste from failed prints, through the test it also highlighted when the print platform wasn’t correctly placed and when there was still filament on the build plate from the previous print.

A feature, shared by many 3D printers, is the heated magnetic P.E.I. sheet print bed, which ensures decent adhesion while printing and makes it relatively easy to remove prints once completed. The great thing about this print platform is that it can be quickly removed and flexed, so tricky prints can easily be detached without resorting to more destructive methods.

Another feature that we initially saw on the CEL-UK Robox machines and materials was the filament detection system, and here when using the AMS system Bambu Lab’s filaments feature a chip that enables the system to auto detect the spool, material and capacity when loaded. If you choose to use third-party filaments, you can manually input some information, using Bambu Studio or the machine’s touchscreen interface.

As the X1-Carbon is capable of printing at speed it features an advanced cooling system, which helps to cool filaments quickly after printing. Part of this design is a chamber exhaust fan that further enhances the cooling process, cooling is an area of 3D printing that we have seen many manufacturers focus on resently, including PRUSA Research in the MK4s.

The features of the X1-Carbon were groundbreaking when the printer was first released, when it set a new standard for 3D printers. What’s remarkable is that, with the subsequent firmware updates since the X1 Carbon has managed to stay up-to-date and, most importantly, relevant.

Bambu Lab X1-Carbon: Performance

There are many aspects that set the Bambu Lab X1-Carbon apart from other 3D printers, especially when it was first released, however, what made it unique then is now common place, so does it remain a standout machine and one of the market leaders, not just as the flagship for the company that makes it?

The quality of design is instantly apparent and as the X1-Carbon is powered up for the first time it runs through its checks to ensure the first and every subsequent model will be printed with absolute quality. As the flagship model from the company, it is slightly more refined than the A1 and P1 series of printers. The solid build, combined with its fully enclosed design, means that it operates less chaotically than those other models. While it still has the issue of ejecting filaments from the back when it swaps filaments using the AMS system (as we noticed in our tests of the other printers), it is quieter.

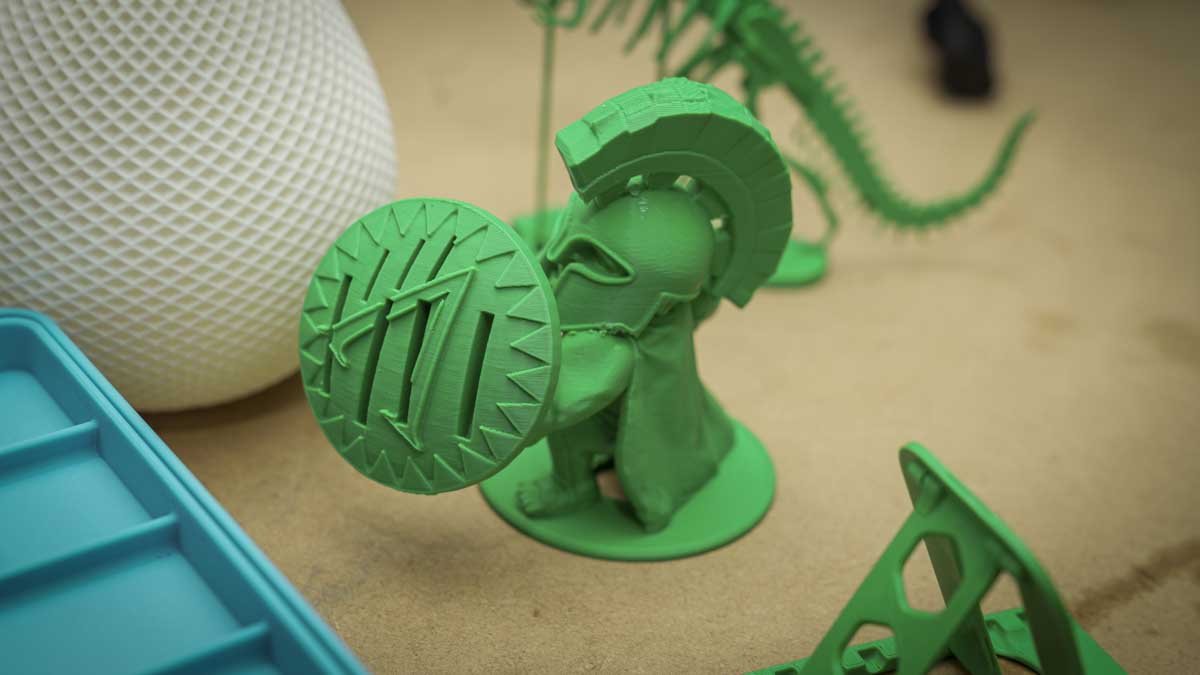

Starting off with a single filament to assess single-filament printing quality and speed, the X1-Carbon instantly impresses with its highly accurate layer application. However, it is worth noting that due to the pre-checks the printer runs through before starting high-speed printing, it does take some time before the first line of filament is laid down on the print platform.

After running quite a few prints through the machine, we decided to switch off some of the pre-checks, which dramatically sped up print times. However, it’s still a good idea to run the calibration process every few prints to ensure the best possible quality especially when printing larger or more complex models.

When printing with a single filament, the overall print quality is absolutely superb and truly market-leading. Only two or three other printers in this price range can compare, such as the original Prusa MK4S and the Creality K1 Carbon.

While other machines can compete with the X1-Carbon in single-filament printing, when it comes to the AMS system and multi-filament printing for colour or material, the X1-Carbon still stands alone. At present, there aren’t many multi-filament options that can really compare to the AMS system, although the K2 will be available soon and AnyCubic’s Kobra 3 system is very similar and also exceptional. Prusa Research also offers the MMU3, which you can add to the MK4S to enable multi-filament printing. However, as an out-of-the-box solution, the X1-Carbon at this level still stands unrivaled as a complete package.

Ultimately, for single-filament printing, the X1-Carbon has several challengers that meet its impressive quality. However, for multi-filament printing straight out of the box, and for absolute ease of use, it is clearly the market leader.

After reviewing the print quality results again, the X1-Carbon does not fail to impress, achieving one of the highest scores of any 3D printer we have tested.

While other machines can compete with the X1-Carbon in single-filament printing, when it comes to the AMS system and multi-filament printing for colour or material, the X1-Carbon still stands alone. At present, there aren’t many multi-filament options that can really compare to the AMS system, although the K2 will be available soon and AnyCubic’s Kobra 3 system is very similar and also exceptional. Prusa Research also offers the MMU3, which you can add to the MK4S to enable multi-filament printing. However, as an out-of-the-box solution, the X1 Carbon at this level still stands unrivaled as a complete package.

Ultimately, for single-filament printing, the X1-Carbon has several challengers that meet its impressive quality. However, for multi-filament printing straight out of the box, and for absolute ease of use, it is clearly the market leader.

After reviewing the print quality results again, the X1-Carbon does not fail to impress, achieving one of the highest scores of any 3D printer we have tested.

Bambu Lab X1-Carbon: Print quality

Dimensional Accuracy

Target 25: X: 24.95 mm / 0.05 mm error | Y: 24.98 mm / 0.02 mm error

Target 20: X: 19.97 mm / 0.03 mm error | Y: 19.96 mm / 0.04 mm error

Target 15: X: 14.97 mm / 0.03 mm error | Y: 14.99 mm / 0.01 mm error

Target 10: X: 9.98 mm / 0.02 mm error | Y: 9.95 mm / 0.05 mm error

Target 5: X: 4.99 mm / 0.01 mm error | Y: 4.98 mm / 0.02 mm error

X Error Average: 0.03 mm

Y Error Average: 0.03 mm

X&Y Error Average: 0.03 mm

Fine Flow Control: 4.8/5

Fine Negative Features: 4.5/5

Overhangs: 4.6/5

Bridging: 4.7/5

XY Resonance: 4.5/5

Zaxis Alignment: 4.6/5

Final Score: 27.7 out of 30

Bambu Lab X1-Carbon: Final verdict

The Bambu Lab X1-Carbon is an impressive machine that still stands out when it comes to multi-filament printing, although when it comes to speed it is now matched by several other machines. While there are a couple of other printers on the market that may beat it in absolute dimensional accuracy, the X1-Carbon as an out-of-the-box solution is one of the best printers available today. What really makes it stand out is not its speed (which some machines surpass), but the quality of the AMS system, ease of use, and the complete ecosystem Bambu Lab has built around their printers. This makes the X1 Carbon fully accessible for everyone, from complete beginners to high-end professionals.

However, the X1-Carbon is not a perfect printer, and there are a few issues from a business perspective. The biggest drawback is that everything is proprietary—if something goes wrong, you need to purchase Bambu Lab parts for repairs, although lead time on parts is generally pretty quick. This means there’s little flexibility for customizing the printer to your specific needs, as you can’t access the system to change or adapt how it functions.

Another issue is the AMS, which, while the easiest system on the market to use, creates a significant amount of filament waste. After every print, it’s worth checking behind the machine to see how much waste has accumulated. However, the machine is very reliable, and the print quality is excellent, so these are relatively small drawbacks in an otherwise outstanding machine.

Should You Buy the Bambu Lab X1-Carbon?

| Row 0 – Cell 0 | Row 0 – Cell 1 | Row 0 – Cell 2 |

| Value: | Highspeed prints at a competitive price | 4.5 |

| Design: | Modern, functional, and compact | 4.5 |

| Features: | Extensive automation and advanced tech | 5 |

| Performance: | Bestinclass speed and accuracy | 5 |

| Total: | A futureforward 3D printer with great value | 4.5 |

For more crafting tools, we reviewed the best laser engravers